Chip-Scale Screening

Rapidly evaluate engineered surface chemistries under controlled shear and fouling environments. Iterate designs weekly instead of quarterly.

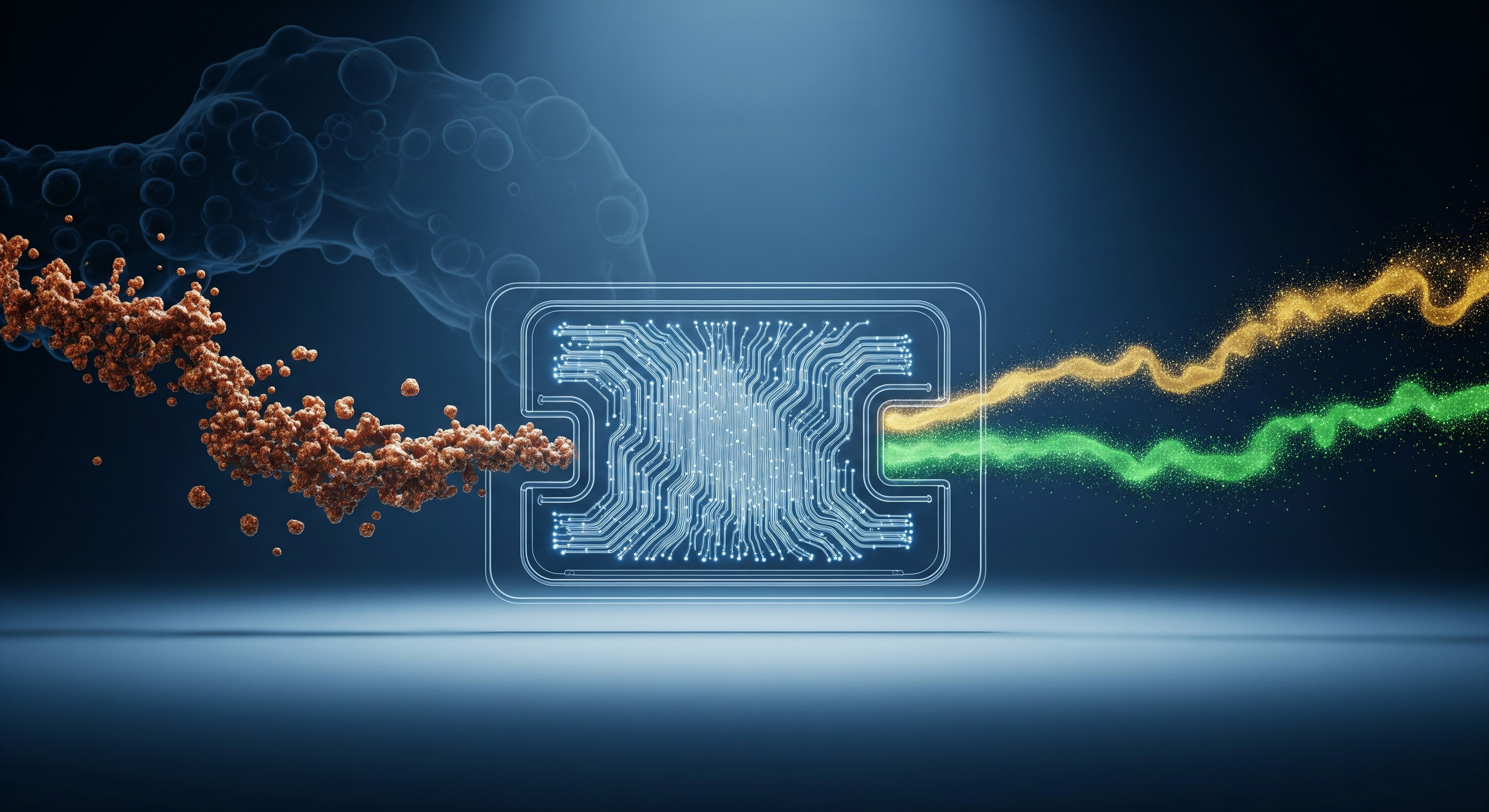

ZOLX engineers a membraneless clarification platform that keeps surfaces clean, reduces ΔP, and scales seamlessly from discovery chips to pilot and plant modules.

Rapidly evaluate engineered surface chemistries under controlled shear and fouling environments. Iterate designs weekly instead of quarterly.

Winners are transferred to coupon and panel hardware using the same coatings, pressure regime, and hydrodynamics validated in assay.

Modular panels snap into existing clarification skids, enabling retrofits with fouling-resistant performance at a pragmatic CapEx.

Our pilot programme is built around quantifiable wins for clarification uptime, shear exposure, and resource consumption.

Target runtime increase versus conventional membrane fouling controls in high-density enzyme broths.

Low-ΔP operation minimizes shear on shear-sensitive proteins and cuts energy draw.

Lower CIP frequency thanks to engineered anti-fouling surfaces and fast in-situ rinses.

Consistent surface chemistry and hydrodynamics across assay chips, coupons, and production-ready panels.

We target tough clarification problems in wet processing. Early pilots focus on enzyme fermentation broths; adjacent opportunities span bioprocessing, dairy/food, and industrial water.

Clarification of high‑density fermentation broths is a known bottleneck due to rapid fouling and frequent CIP. Our fouling‑resistant, low‑pressure panels are designed to extend runtime and protect downstream steps, with a pragmatic pilot path.

For shear‑sensitive cells and proteins, low‑pressure operation helps maintain viability and activity. Our approach aims to minimize filter consumables while sustaining flux without harsh shear.

Membrane processes in dairy and beverage are productive yet fouling‑limited, driving cleaning time, water, and chemical use. Our fouling‑resistant panels aim to extend run length and cut resource consumption.

Polishing oily or particulate‑rich side streams benefits from surfaces that resist cake formation while enabling selective handling of target fractions.

Tell us about the clarification challenge you are tackling. We will schedule a focused session to align on feed chemistry, performance targets, and deployment timeline.